Meeting the Challenge of Global Logistics and Support for Large Power Transmission Projects

“The key to supplying and supporting large, operationally critical

power transmission equipment on a global basis is a combination of

experience, planning and having the right people available on-site

virtually anywhere in the world,” says Neil Wright, managing director

of Wichita Clutch.

Wichita is part of the Altra Industrial Motion group, which

manufactures and supplies a large range of industrial clutches, brakes,

couplings and geared motors. As such it can provide valuable insight

into how to deliver and support these sometimes huge and usually

operationally critical items of plant equipment.

Wright, who is also the managing director of Twiflex Limited,

comments on where to locate stock; if point of manufacture matters;

what to consider when shipping; and how to manage commissioning

and local support. “There are several criteria which come into play

when supplying large items of power transmission equipment on a

global basis. The ability to both deliver and provide effective technical

support for a large item of plant equipment, anywhere in the world,

is critical to success. The performance of a supplier on an ongoing

basis is also crucial to maintaining a positive working relationship and

helping to achieve the customer’s objectives, whether that is to lay a

cable across the Atlantic, commission an oil rig, produce steel or even

make an island – all of which are applications where Wichita clutches

can be found.”

When you manufacture a niche product, the knowledge and

machines required to design and manufacture each item, often to a

custom specification, have to be concentrated in a limited number of

locations. “This means that we have to be highly proficient with our

distribution and delivery network, which is why we have a department

dedicated to world-wide logistics and have done so for over 50 years.

Paperwork requirements vary wildly depending on final destination, so

it is essential for us to have continuity in that department, to learn the

most effective ways of doing business and to continue to build-up our

cache of local knowledge,” adds Wright. “When handling paperwork,

communication and coordinating after sales support on a global basis

it is essential to have local sales offices in every major country that we

sell to. It has been a strategic focus for Altra to have a global network

of sales offices across North America, South America, Europe and

Asia and therefore it is likely that direct after sales support, from a

local speaking national, is never far away.

“For commissioning we predominantly use our own people to

complete or oversee a build; we have teams that are trained to handle

our products and can travel to most locations in the world. We also

have international support engineers that can be deployed locally on

all the major continents. We find that having our own people on-site

means that we can work more efficiently and any questions can be

answered and issues addressed immediately.”

When selling smaller, more standardized or commodity based

items of power transmission equipment, in-country distribution

partners and third party sales support make perfect sense. However,

when you are dealing with high-value capital pieces of equipment,

where each application is different in some way, then there are

too many variables to leave the task to someone who isn’t a

total specialist. A good way to illustrate how the organization

accommodates both sales and ongoing support is to look at a typical

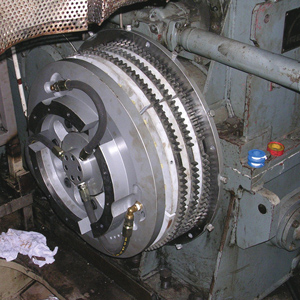

example: Wichita recently designed, manufactured and delivered a

large 42” Wichita MSV series marine clutch for a dredging ship. “We

have supplied several large clutches to dredging ships before, so there

was a degree of accumulated knowledge within the company on this

type of application. This one, however, was larger than anything we

had produced before,” Wright said.

The clutch couples a three-speed gearbox to a large on-board

pump, which is used to provide suction to a trailing hopper that

takes-up the river or sea bed and stores it in the ship’s hold. It then

changes its operation and is used to empty the hold, either to build-up

banks or disperse the material. “Our direct customer is the gearbox

manufacturer, so we first started to speak to them about the design

and specification of the entire application. In this instance this was

the largest version of this arrangement ever produced so it involved us

designing a bespoke clutch to meet the specifications of this project.

Whether a project is large or small, most products with this type

of large power transmission system are custom manufactured to a

greater or lesser degree; though often based on an existing design.

Proper consultation is absolutely essential and, if we are designing to

a specification, then it is always best if we can be involved in forming

that specification,” Wright said.

Being involved in the design process from the outset is a good

example of how the organization works around producing a large

piece of custom PT equipment. “We know that we have to be able to

provide engineering input from an early stage and commit engineering

and design resources to the project before we even start planning

the design of the clutch itself. This carries a large overhead, as does

maintaining our own logistics teams and commissioning engineers,

but it also ensures we are profitable by avoiding the pitfalls of

misspecification and out of sequence deliveries.”

Once the design and specification process is complete, the

company then designs and manufactures the clutch. In the case of

the dredger mentioned above, the gearbox assembly will be supplied

to the shipyard for integration into the ship, which means supplying

essentially a collection of parts to the shipyard. “We will provide an

engineer/project manager to oversee the assembly and construction

of the clutch and then observe the sea trials to make absolutely sure

the equipment is performing as expected,” Wright added. “To many

companies this may look like overkill, but there are so many variables

in a bespoke build of this scale that we find being on-site means we

can react to any potential issues as, or even before, they arise. This

helps to minimize any potential problems and ensures the project stays

on track for our customer. We also go through a thorough check and

sign-off process to make sure we are satisfied that the application is

working to its operating parameters.”

“The alternative to these checks can be far more difficult and

costly. If we are called to look at an issue which arises while a ship

or rig is in service, then this can involve flying out engineers (and

sometimes tools and parts) to remote parts of the world, finding

connecting transport and then possibly helicopter flights out to the

vessel itself. Of course our operatives are fully-trained for such an

eventuality, from basic site safety through to working in offshore

environments, but if we can catch a problem prior to deployment

then that is obviously preferable. Often we find that the root cause

is not connected with the clutch, but our primary concern is to help

resolve the problem. “When required by our customers we can apply

a structured problem solving approach, such as ‘8D,”’ to resolve

problems. Using this process we look to identify, correct and eliminate

any recurring problems. It then allows us to establish a permanent

corrective action based on analysis of the problem; focusing on the

origin of the problem and determining its root causes. It is this kind

of commitment and attention to detail that we find leads to repeat

business – you have to be able to trust and rely on your suppliers,

after all.

“Large power transmission projects tend to be by their very

nature unsuitable for ‘catalogue solutions’. Our expertise in such

applications allows us to add value to the design process: we work

with design engineering departments and help to integrate our CAD

models with those of the customer so it is possible to drop them

straight into the design. This early partnership saves time and reduces

project costs before metal is cut.

“Every company works differently, but when selling and

supporting heavy duty clutch and brake products throughout the

world, we have developed a model that works for our customers. It is

a ‘belt and braces’ approach, as we would say in the U.K. -applying

engineers early in the process, taking care of the logistics internally

and providing sales and support engineers throughout the world

(covering China, Russia, Europe, Asia and the Americas) to look

after projects directly - but it results in us being an efficient, reliable

supplier in a market that has little or no margin for error.”